-

Highlight

custom membrane switch

,membrane touch switch

-

SurfaceGloss/Matt

-

CircuitFlexible Printing Circuit/ PET Circuit

-

UsageControl Switch

-

MaterialPET/ PC

-

TechnologySilk Screen Printing

-

FeatureWater-proof

-

Place of OriginChina

-

Brand NameTKM

-

CertificationISO9001:2015, SGS,Rohs

-

Model NumberTKM-011

-

Minimum Order Quantity100pcs

-

Pricenegotiable

-

Packaging DetailsPolybag per pcs,50per cartoon

-

Delivery Time15-20days

-

Payment TermsL/C, T/T, Western Union

-

Supply Ability1000000Pieces per month

Embossing Control Switch 4-LEG Metal Dome With Embedded LED

![]()

Custom Membrane Switch Manufacturer

TKM is a membrane switch manufacturer with many years of experience in this line.Our team has extensive experience creating membrane panels for a variety of uses for our clients. Learn more about the membrane switch production process below and contact us for more information about how we can create the product you need.

What are Membrane Switches?

A membrane switch is a user interface device that is made up of several layers and used as a switch to turn a device on or off. Unlike mechanical switches, which are generally constructed with copper and plastics, membrane switches are printed circuits on film.

How do Membrane Switches Work?

The design behind most membrane switches is simple: when an operator wants to use the device, a switch is pressed so that the system’s two poles make contact and close the circuit. When the switch is released, the poles are disconnected and the switch returns to its open state.

How are Membrane Switches Made?

The design and manufacturing process behind membrane switches is one TKM handles with much care and creativity. Membrane switches are made by printing a carbon or silver ink onto a polyester surface. A customized graphic overlay is then applied to the film. At TKM, we offer a wide range of graphic layer material, including polyester, antimicrobial polyester, polycarbonate, blends, and silicone. These pliable, durable materials are where “membrane” switches get their name.

![]()

Product construction

![]()

Where are Membrane Switches Used?

Membrane switches are used in a number of applications, including in medical, aerospace, defense, industrial, and transport industries. They are often used for keypads, control panels in aircrafts, touch screen phones, and kidney dialysis machines—just to name a few.

Membrane switches are revered for their durability and flexibility, especially in high or low-temperature environments. They are also known for their reliability and high conductivity.

Types of Membrane Switches

There are two main types of membrane switches, each performing different functions on the circuit board:

Tactile. Tactile switches are designed to provide a response when pressed by an actuator or finger. An overlay over the switch has symbols or letters used to designate the function of each switch. Generally, these switches are designed using metal domes. When pressed, the metal dome pushes against a conductive footprint, causing an action to happen.

Non-tactile. This type of switch operates with the same concept of a tactile switch but does not elicit a tactile response. With the bottom of the overlay connecting to a conductive pad, non-tactile switches are self-contained units.

At GGI Solutions, we provide a variety of membrane switches for applications in medical, aerospace, defense, industrial, and transport industries. Our engineering and design teams are committed to providing you a durable, reliable, and eco-friendly product, guaranteed to improve efficiency within your business. Contact us today for more information about our products.

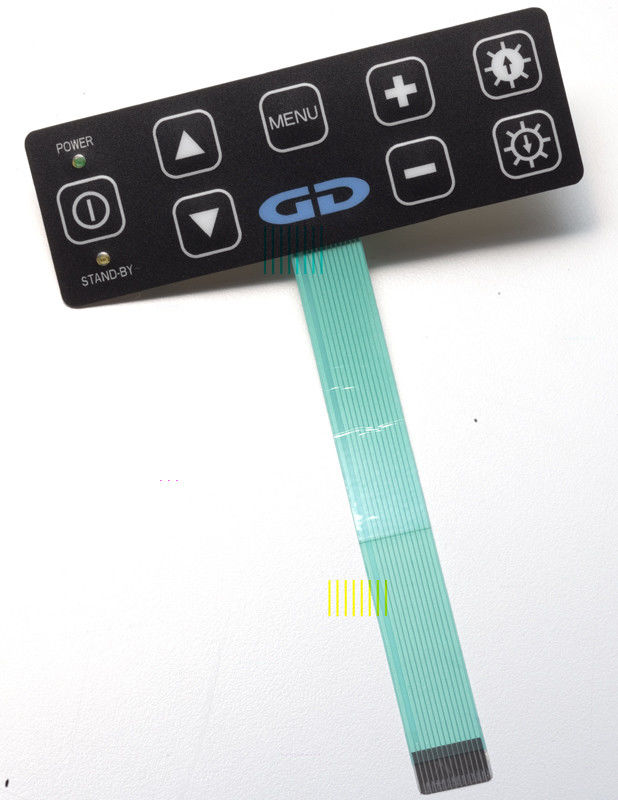

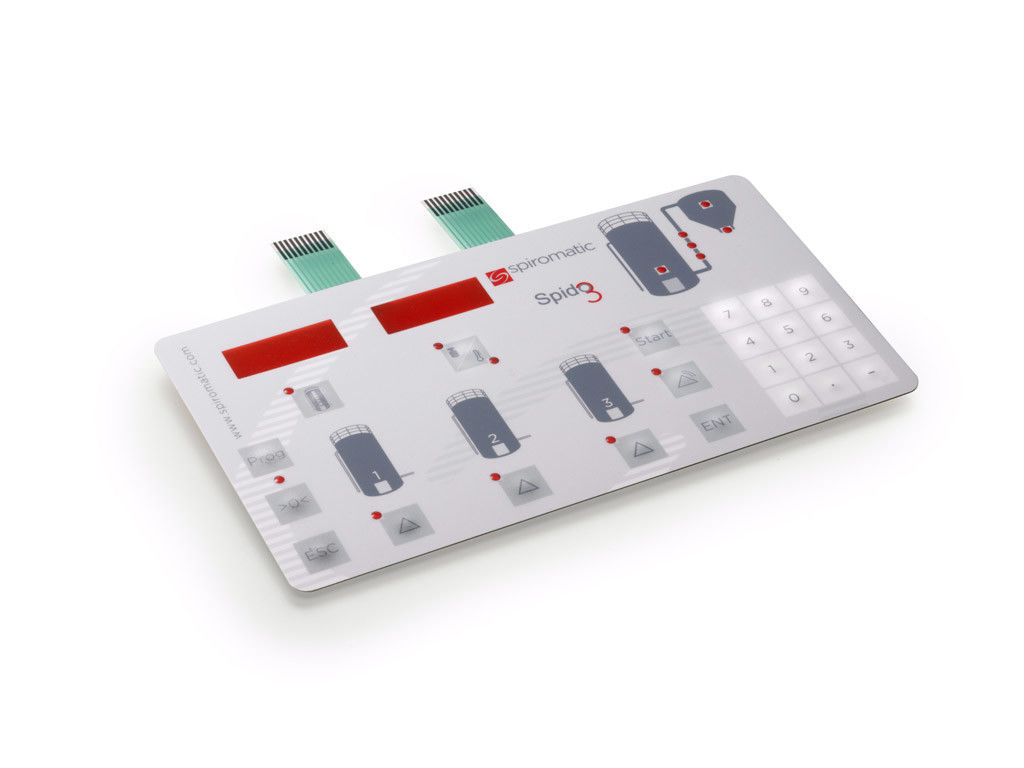

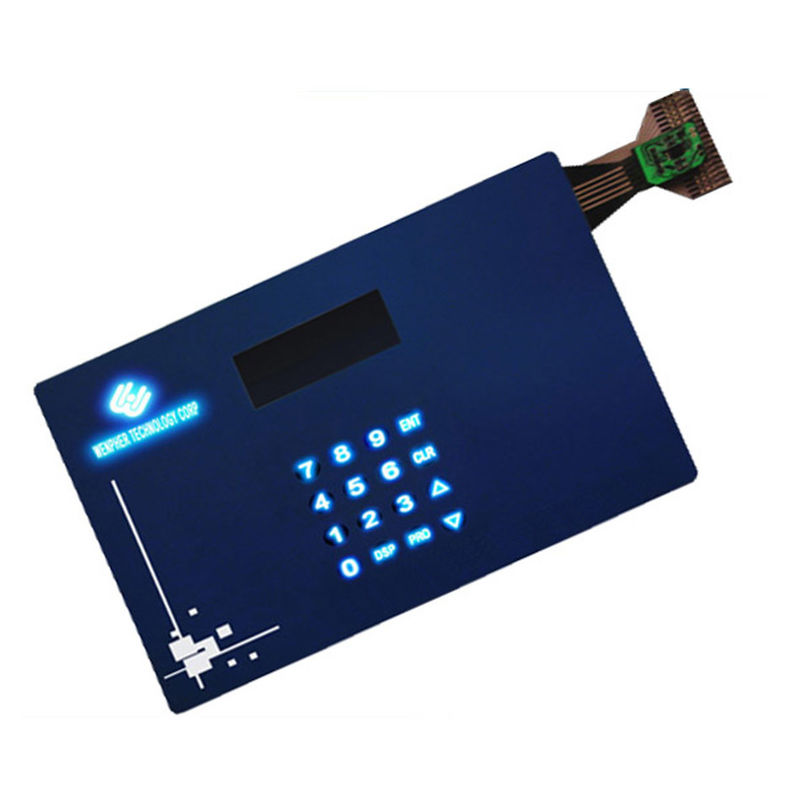

Product show

![]()

![]()

![]()

Workshop

![]()

1. OEM Order welcome: Product, Package...

2. Sample order Before mass production

3. We will reply you for your inquiry within 24 hours.

4. After sending sample, we will provide tracking number,when you got sample, test sample, if there's problem with the sample, please contact with us, we will solve problem at the first time.