Metal Dome Waterproof Tactile Membrane Switch For Mobile Phone

-

Highlight

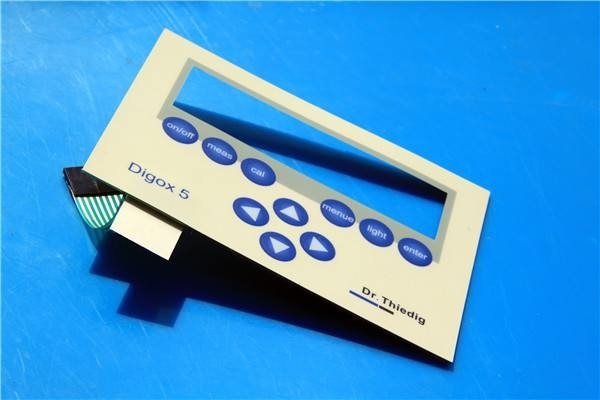

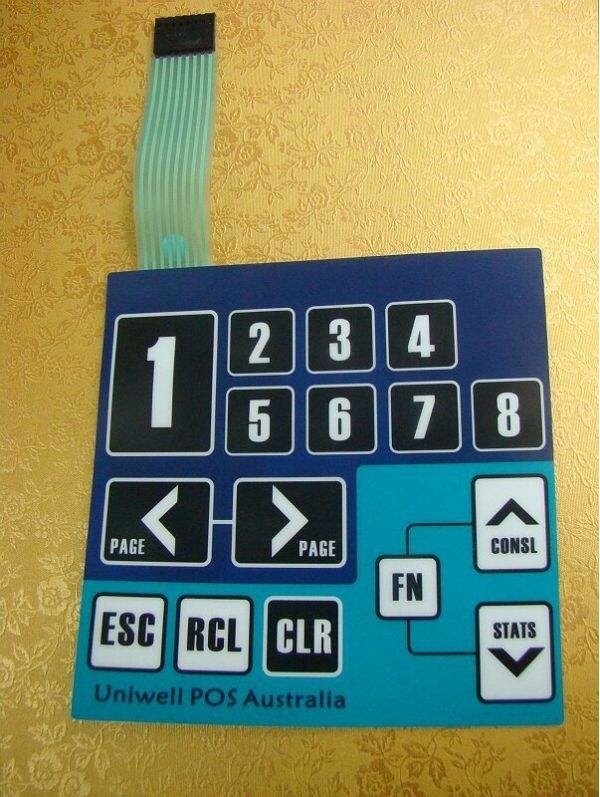

Waterproof Tactile Membrane Switch

,Metal Dome Tactile Membrane Switch

,Metal Dome Waterproof Tactile Switch

-

Place of OriginChina

-

Brand NameTKM MS

-

CertificationISO9001:2008, SGS,Rohs

-

Model NumberTKM—MS--303

-

Minimum Order Quantity100pcs

-

Pricenegotiation

-

Packaging DetailsPolybag per pcs,50per cartoon

-

Delivery Time15-20days

-

Payment TermsT/T or L/C

-

Supply Ability100000Pieces per month

Metal Dome Waterproof Tactile Membrane Switch For Mobile Phone

Metal Dome Membrane Switch/Tactile Membrane Switch/Waterproof Tactile Switch

Introduction:

Membrane switch, also known as light touch keyboard, is made of PC, PVC, PET, FPC and double-sided adhesive and other soft materials, using screen printing technology produced by the multi-plane combination seal set graphics, keys, symbols display, electrical conductivity and electronic switch functions in one of the plastic electronic products. The main characteristics of the film switch are: 1, small and light: the weight of the general film switch is a few grams to dozens of grams, very easy to carry and disassembly.

Description:

The main technical indicators

1. Max size: single sided, double sided:600mm * 500mm Multi-layer: 400mm * 600mm

2. Processing thickness:0.2mm -4.0mm

3. Copper foil substrate thickness: 18μ(1/ 2OZ ),35μ( 1OZ ),70μ( 2OZ )

4. Common material: FR-4 , CEM-3 , CEM-1, Polytetrachloroethylene,FR-1(94V0,94HB)

5. Light copper,Nickel-plated,Gilded,HAL;Immersion Gold,Antioxidant,HASL,Immersion Tin,etc.

Applications:

1. The mobile phone

Focuses on the flexible circuit board light weight and thin thickness. Can effectively save the volume of products, easy connection of the battery, microphone, and buttons and into one.

2. Computer and LCD screen

Use the one line configuration of flexible circuit boards, and thin thickness. The digital signal into the picture, through the LCD screen

3. CD player

Focuses on three dimensional assembly characteristics of flexible circuit boards and thin thickness. The huge CD to carry around

4. Disk drives

Regardless of the hard disk, or diskette, is very dependent on FPC high softness and thickness of the 0.1 mm slim, read data finish quickly. Either a PC or NOTEBOOK.

5. The latest applications

Hard disk drives (HDDS, hard disk drive) of suspended circuit (Su ensi. N cireuit) and the components of xe packaging board, etc

Specifications

Type | PCB | Application | Electronic Products |

Color | blue | Feature |

|

Machine Stiffness | Rigid | Lays | Customized |

Material | PET /PC | I nsulation Material | Organic resin |

I nsulation layer thichness | General | Antiflaming Speciality | VO |

Processing Technic | Rolled foil | Reinforcing material | Glass fiber |

Insulating Resin | Polyimide resin | Export Markets | Global |

Process Capability

1. Drilling:The minimum diameter 0.1mm

2. Hole metallization:Minimum aperture 0.2mm,Thickness / aperture ratio 4:1

3. Wire width: Minimum:Gold plate 0.10mm, Tin plate0.1mm

4. Wire spacing: Minimum:Gold plate 0.10mm, Tin plate0.1mm

5. Gold plate: nickel layer thickness:≧2.5μ,Gold layer thickness: 0.05-0.1μm or according to customer requirements

6. HASL: tin layer thickness:≧2.5-5μ

7. Paneling: Line-to-edge minimum distance: 0.15mm hole to edge minimum distance: 0.15mm smallest form tolerance: ± 0.1mm

8. Socket chamfer: Angle: 30 degrees, 45 degrees, 60 degrees Depth: 1-3mm

9. V Cut: Angle: 30 degrees, 35 degrees, 45 degrees Depth: thickness 2/3 Minimum size: 80mm * 80mm