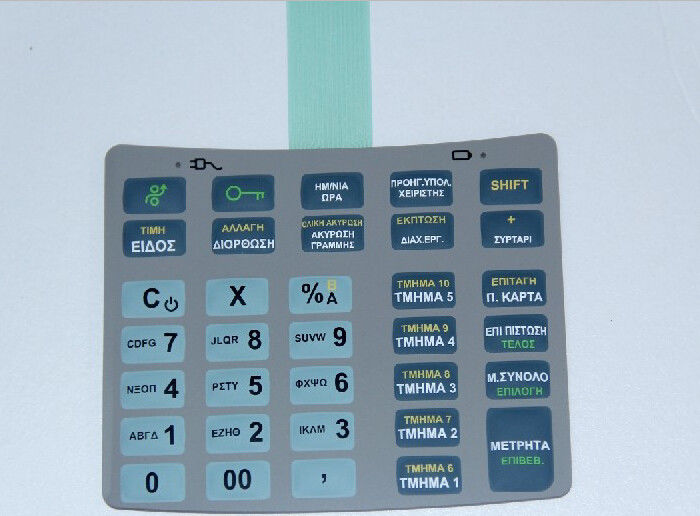

Waterproof SGS PC Rubber Membrane Switch With 3m Adhesive , 25ma - 100mA

-

Highlight

membrane panel switch

,membrane key switches

-

Place of OriginChina

-

Brand NameTKM MS

-

CertificationISO9001:2008, SGS,Rohs

-

Model NumberTKM-MS--160

-

Minimum Order Quantity100pcs

-

Pricenegotiation

-

Packaging DetailsPolybag per pcs,50per cartoon

-

Delivery Time15-20days

-

Payment TermsT/T or L/C

-

Supply Ability100000Pieces per month

Waterproof SGS PC Rubber Membrane Switch With 3m Adhesive , 25ma - 100mA

SGS PC Quakeproof Rubber Membrane Switch With 3m Adhesive , 25ma-100mA

Quick Detail:

|

Name |

Silicone MS |

Life time |

>1 Million times

|

|

Color |

Transparent,red,yellow, green,blue.Pink.,purple |

Feature |

3M467 adhesive & PET/PC |

|

Insulation resistance: |

<100MΩ,250V DC |

Certificate |

RoHS |

Description:

Silicone Telephone Keypad are the most popular user interface for a variety of reasons. They offer design flexibility at a low per unit cost. Some of the design options include:

Integrate Multiple Silicone Colors

Choose From a Variety of Materials

Print Multiple Colors for Text and Legends

Laser Etched Legends for Back Lighting

Coating Options for Increased Durability

Chemical and Environmental Resistance

Liquid Injection Molded Products

Plastic Key Caps

Metal Keypads - Durable Construction, Custom & Stock Designs

Carbon, Gold, and Copper Contacts

Applications:

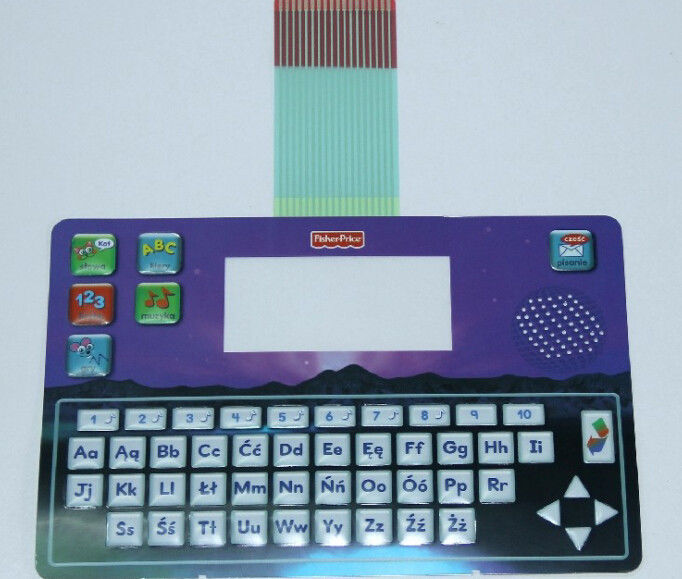

1. The backlight applications: all kinds of electric computers, laptops, handheld game consoles, telephones, electronic organizers, electronic dictionaries, audio equipment, control panels, microwave oven control panel, fax machines, copiers, watches ...... etc.

2. Automotive: Car instrument panel, warning lights, vehicle exteriors, decorative door bar, third brake light ...... etc.

3. Architecture and interior applications: elevator floor marking, labeling instructions escape, decorative wall lights, night landscape decorative building, interior decorating

4. Toys, gifts: all kinds of toys, light source, light frame, EL photo, Valentine's cards, badges and other consumer product applications

5. Public places of business equipment, machinery: bus stop, public phone booths, coin-drinks machine on the bus route licensing ...... etc.

Specifications

|

Contact resistance |

10 to 500Ω (varied from the trace length and material) |

|

Tactile type life expectancy |

1,000,000 closures or more |

|

Maximum circuit rating |

35V DC, 100mA, 1W |

|

Operating temperature |

-40 to +80C |

|

Storage temperature |

-40 to +85C |

|

Tactile type actuation force |

150 to 400g (6 to 14oz) |

|

Contact bounce |

5ms or less |

|

Dielectric withstand |

250Vrms (50 to 60Hz/minute) |

|

Tactile type switch stroke |

0.6 to 1.5mm |

|

Insulation resistance |

100MΩ at 100V |

|

Surface hardness |

3H or more |

|

Operating humidity |

90 to 95%RH (at 40C ) for 240 hours |

Competitive Advantage

Silicone Rubber Molding and Keypads

QUALITY: High quality equipment and materials provide durability and consistency in your product. HHC is a family owned and operated business and has many years experience in manufacturing Silicone Rubber Keypad, Silicone Telephone Keypad etc.

PRICING : HHC offers world class service and pricing. And we have developed tooling methods that can save the customer thousands of RMB off standard prices!

FREE DESIGN: Our rubber tooling cost includes 3D modeling from a 2D file at no additional cost. We can also reengineer a keypad from a customer provided sample at no additional cost. Our engineering staff has designed kinds of silicone keypad and can offer free design assistance.

PROTOTYPES: Our standard lead times are among the best in the industry. However, if you need something faster RSP has developed a process for manufacturing short run production quality silicone rubber keypad in 7-10 days. Keypads can be done in multiple silicone colors with multiple print colors for no additional charge.